By Abhijit Roy December 18, 2022

Imagine you’re standing at the edge of a wheat field in Punjab. In the distance, a combine harvester guided by GPS rolls across a field that has been leveled with the aid of a laser, as the farmer at the wheel monitors weather data on his or her phone. These tools, part of an approach to agronomy called precision agriculture, promise to increase yields, and reduce costs by maximizing efficiency. That could help ensure the world grows enough food to feed an expanding population, even as climate change makes that task ever harder. Making most of this possible is, Digital Twins, a technological innovation transforming the industrial world.

Digital Twin market poised to cross US$73 billion

Digital Twins, a digital replica of a physical object to observe its real-time performance, gather data, and recommend corrective actions if required to enhance its performance, is sweeping the industrial world like wildfire. The Digital Twin market is expected to grow at a CAGR (compound annual growth rate) of over 60% to reach US$ 73.5 billion by 2027, from US$6.9 billion in 2022, per MarketsandMarkets research. This fascinating technological idea is now reaching the agriculture fields to transform farming, by creating digital twins of entire farms.

Technology removing uncertainties

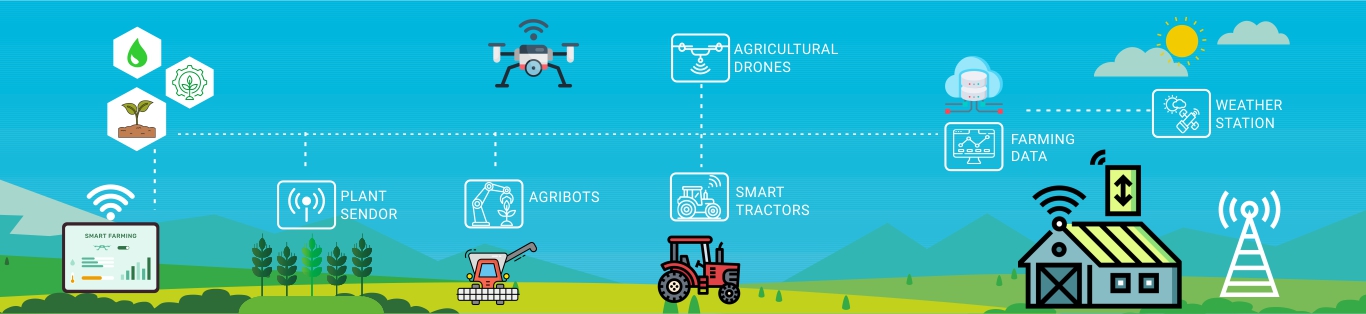

Satellite or drone scans of entire fields and crops capture one and three dimensional images, sensor data from soil, data from connected farm equipment like tractors, harvesters, and even livestock data from RFID tags and collected, stored in cloud servers, and analyzed to create a real-time digital twin of a farm, for monitoring the entire operations. It is fascinating to extract actionable intelligence from a time-lapse image of over 18 months using Nvidia accelerated image recognition to understand plant growth. Agriculture scientists feel that Digital Twins would be invaluable in removing a lot of uncertainties around plating and growing crops, rearing farm animals, and supporting precision farming.

Ingreens platform disburses US$1 billion in direct benefit transfer to farmers

Ranadeep Das, CEO of Ingreens, India’s fastest growing AgTech company was confident that Digital Twins of farms was the way ahead work on which has already started. He said; "We are digitizing large swathes of farming activity; from satellite images to embedding sensors in the soil, from monitoring crop conditions with drones, to connected farm supply chain vehicles. Integration of all these data sources are logically leading to creating digital twins of farms. It is already work in progress.

Ingreens is creating a platform that will integrate and analyze data from multiple sources to enable such real-time tracking with intelligence to recommend actions." Das and his teammates at Ingreens have already delivered a swathe of SaaS (software-as-a-solution) solutions to deliver last mile value to farmers, including use of satellite data to accurately calculate farm yield data, based on which farm insurance premia is decided and claims settled with minimal scope for disputes. Speaking to farmers in the field one gets a feeling that the solution is working without a hitch. The company has onboarded nearly 9 million farmers on its platform, and disbursed almost US$1 billion as direct benefit transfers of government financial support to agriculturalists. This can now be scaled up across the country as a plug-and-play model that can be implemented in a week’s time.

Siemens takes Digital Twins underwater

German technology company Siemens has even taken Digital Twins underwater. Siemens and Nemo’s Garden announced an entirely new use case: a reliable method of cultivating herbs, fruit, and vegetables underwater. Founded in 2021 by the President of Italian scuba diving equipment manufacturer Ocean Reef Group, Nemo’s Garden has an ambitious goal: to create an entirely new system of agriculture that doesn’t rely on traditional methods or the variability of typical ecosystems and uses less ecological resources. They are focused on “areas where environmental conditions, economical, or morphologic reasons make plants growth extremely difficult.” They are growing plants in biospheres under the ocean. But the challenge was in monitoring the biospheres continuously.

The team has built a comprehensive digital twin of the current biosphere model. Using Siemens’ Simcenter™ STAR-CCM+™, the Nemo’s Garden team can simulate growing conditions inside of the biosphere and how the biosphere might affect the flow of water around it to minimize impact to the natural ecosystems where they’ll eventually be placed. With this digital twin, Nemo’s Garden doesn’t have to wait for real-world weather conditions or seasonality — or keep putting divers into risky situations — to quickly understand how they can refine their design.

The team uses digital twins and machine learning to monitor the health of their crops using automation, to eventually eliminate the need to send trained divers underwater. With its MindSphere service, Siemens used video of crop growing cycles and compared it to traditional farming to create an algorithm that monitors plant growth holistically.In the future, Siemens will deploy its Industrial Edge computing devices in each biosphere and connect them to actuators to automatically adjust air circulation, irrigation, and nutritional dosing throughout an entire growing season. That’s how Nemo’s Garden imagines scaling its business to a global agricultural service that can be deployed in any ocean.

Microsoft steps into agriculture platform

Technology companies have already this as a highly exciting and profitable emerging business opportunity. Australian agricultural technology start-up Agronomeye has collaborated with Microsoft and Australian government agency the Commonwealth Scientific and Industrial Research Organisation (CSIRO) to develop the AgTwin platform, which create digital twins of farm properties using real-time data. The AgTwin platform uses high-resolution maps of farms and modelling techniques to produce the digital twins, which present data including the flow of water across the property and soil moisture profiles. There is an incredible amount of data available to farmers, but being able to integrate it, apply it directly and specifically to their own farms, and act on it, has been difficult. Agronomeye unlocks this capability in a far more engaged, practical way, claims the company.

Azure FarmBeats is a research project from Microsoft Research that has developed into a data integration and aggregation platform in the cloud. It brings together multiple agricultural data sets, including data sourced from in-soil and on-farm sensors, satellite imagery and drones as well as Bureau of Meteorology data, which can then be analysed using artificial intelligence (AI) and machine learning.

Ushering in ultra-precision agriculture

The U.S. Artificial Intelligence Institute for Resilient Agriculture at Iowa State University is one of four groups building that proverbial sink with what it calls ultra-precision agriculture. The institute hopes to, over the next three to five years, use data science, machine learning and other artificial intelligence technologies to provide corn and soybean growers with personalized recommendations that will boost crop production. The tools also could help industry scientists develop seeds that deliver higher yields while resisting drought and other stressors.

This will become increasingly important as drought and desertification shrink the world’s acreage per capita of arable land, and the world’s population balloons to 9.7 billion by 2050. As researchers look to artificial intelligence, drones, and robotics to help agronomists prepare for this future, industry analysts expect the global market for precision agriculture, valued at $4.84 billion in 2018, to reach $10.16 billion within two years.

The institute plans to create what’s called a predictive “digital twin” framework — a tool used to virtually model anything from a single plant to an entire farm (creating a digital copy, or twin, of the real-life environment). Such a tool can quickly and easily test myriad scenarios for everything from the optimal amount of nitrogen to apply to a field to which hybrid plants to cultivate. Engineers in industries like aviation rely on such models to determine when, say, an airplane might require repairs. Bringing the technology to agriculture has the potential to help agronomists make day-to-day decisions and future plans with greater certainty and efficiency.

Beyond quickly testing hypotheses or seeing how decisions big and small might play out, the digital twin framework could allow farmers to vastly expand their expertise by combining two traditionally siloed types of data: Even as the models continuously assimilate data on things like weather, soil composition, and plant genetics, they will draw on the collective knowledge of farmers, botanists, and others.

Challenges to be solved

However, implementing Digital Twins in farm management is a challenging task. The highly dynamic production system in agriculture (process dynamics) poses requirements that go beyond many other sectors concerning the capabilities of Digital Twins to mirror dynamic behavior. In such a dynamic environment, it is really challenging to get seamless access to object data while ensuring the integrity of data and respecting usage rights, safety, and security. Furthermore, real-time synchronization can be complicated in rural areas, which often have limited coverage and bandwidth.

Farms are part of a dynamic network and share data with many stakeholders including customers, input suppliers, farmer cooperatives, advisors, contractors, and certification and inspection organizations (network dynamics). These stakeholders may also have access to the farmer's Digital Twins, but limited to the information that they need. This implies that there must be interoperable solutions for providing external access to specific views on Digital Twins in a secure and trusted way. Vice versa, external stakeholders can enrich farm Digital Twins with a wealth of (3rd party) archives such as historical and forecasted meteorological data, satellite data, soil-, water- and air-analyses, etc. There should be proper mechanisms in place to dynamically integrate these data in farm Digital Twins.

Agricultural products are living objects that inherently are diverse and are characterized by complex behavior. Moreover, farms don't have one Digital Twin of concern for smart farming, but they are composed of a large variety of interrelated objects (object complexity). Main objects are i) inputs including seeds, feed, fertilizers or pesticides, ii) throughputs including objects in production (e.g. growing crops or animals) and resources including fields, stables, machinery and personnel, and iii) agricultural output including harvested (lots of) crops, animals ready to be slaughtered, etc. Digital Twins of a fine granularity level, e.g. up to individual plants or animals, would add more value, but are also more difficult to implement, which results in higher costs. In case of a fine granularity, a key challenge is to manage the interdependences between (sub) Digital Twins at different granularity levels.